Maximize Your Engineering Design with FEA Consulting Services

Are you in need of top-notch Finite Element Analysis consulting services for your engineering projects? Look no further than American Engineering Group, your go-to FEA company for all your Finite Element Analysis (FEA) engineering needs.

Finite Element Analysis (FEA) Services

FEA Consulting: Enhance Your Product's Performance with Our Comprehensive Engineering Design Solutions

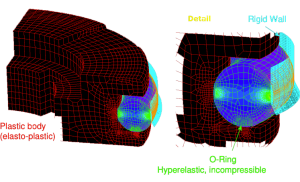

At American Engineering Group LLC, a leading FEA company, we comprehend the significance of enhancing product design and development through optimization. That’s why we offer a wide range of specialized FEA Services and Consulting, including FEA Simulation, Analysis, and much more. Our consultants have 20+ years of experience and provide accurate results for clients in different industries. We offer comprehensive FEA services for composites, plastic, and rubber materials using the latest simulation techniques and software such as ABAQUS.

Our company has extensive experience in this field. Moreover, our expertise not only guarantees visually appealing products, but also ones that are structurally strong and economically manufactured. Improve product performance and reliability with our Finite Element Analysis services.

Our FEA consulting engineers are highly skilled in areas such as stress analysis, linear dynamics, ASME pressure vessel analysis, nonlinear contact analysis, and plastic thread design, among others. We work closely with each client to understand their specific needs and provide customized solutions to meet their requirements.

At AEG, we are dedicated to providing professional, yet affordable Finite Element Analysis FEA consulting services. Trust our experienced FEA consulting engineers for all your product development needs. As a leading FEA company, American Engineering Group has been providing top-notch FEA consulting services for over 20 years. Our aim is to enhance the design, longevity, and reliability of your products through our exceptional FEA consulting services.

Our finite element analysis services accurately simulate operating conditions to predict the performance of your product under real-world scenarios. Contact us today to take advantage of our expertise and experience.

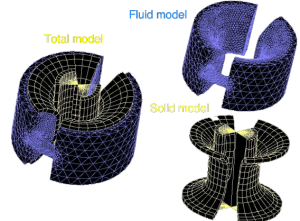

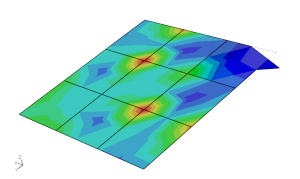

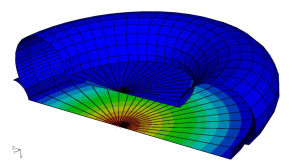

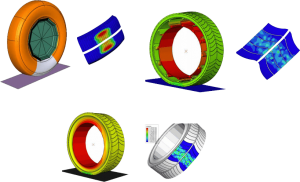

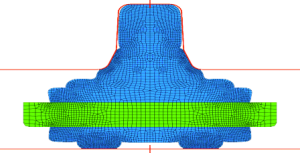

FInite Element Analysis Work

Get precise engineering solutions with AEG’s top-notch FEA consulting services. Our company’s exceptional work showcases our commitment to delivering high-quality design and analysis. No matter the project, our goal is always to exceed our clients’ expectations with exceptional FEA consulting services.

WHAT AEG’S FINITE ELEMENT ANALYSIS (FEA) SERVICES AND CONSULTING CAN OFFER YOU:

Some of the components analyzed by our FEA

Looking to minimize costs and improve your existing designs? For expert finite element analysis services, look no further. Our experienced engineers are here to provide you with high-quality design and analysis services. We offer FEA, CFD, and Mold-flow analysis.

Whether you’re looking for Basic component stress analysis, Complex physics simulation and testing. We’re here to help you achieve better results with our Optimization studies, Trade-off studies, Sensitivity studies.

Our company will help you design better products. In case of engineering failures, we provide in-depth root cause analysis using FEA, CFD, and testing services. Furthermore, our services extend to:

- Product recall

- Expert witness

- Litigation

- Patent infringement engineering support work

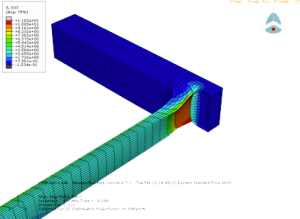

Thanks to our ABAQUS software, we have the capabilities to handle even the most complex nonlinear situations. Our core consulting areas include:

- Nonlinear stress analysis

- Material plasticity

- Nonlinear materials, including hyperelasticity, elastoplasticity, viscoplasticity, and creep

- Nonlinear buckling and post-buckling

- Nonlinear contact, including frictional contact and geometrical

Trust us to help you achieve optimal performance and design with our FEA simulation services and consulting.

AEG'S FINITE ELEMENT ANALYSIS (FEA) CAPABILITY

AEG provides comprehensive engineering simulation services with Finite Element Analysis technology. Our team of experts has over two decades of experience in FEA. They can handle any complex engineering challenge and help you turn your product designs into a reality. Let AEG show you the full capabilities of FEA and help you reach your goals:

Structural Analysis

- Linear static analysis

- Nonlinear static analysis

- Linear dynamic analysis

- Nonlinear dynamic analysis

- Modal analysis

- Transient analysis

- Fatigue analysis

- Fracture mechanics analysis

- Buckling analysis

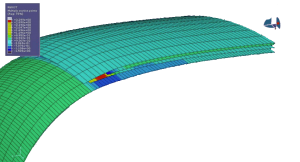

Thermal Analysis

- Steady-state thermal analysis

- Transient thermal analysis

- Nonlinear thermal analysis

- Structural thermal analysis

Fluid Dynamics Analysis

- Steady-state fluid flow analysis

- Transient fluid flow analysis

- Nonlinear fluid flow analysis

- Fluid-structure interaction analysis

Multiphysics Analysis

- Thermal-structural analysis

- Thermal-fluid analysis

- Structural-acoustic analysis

- Electromagnetic-thermal analysis

Acoustics Analysis

- Modal analysis

- Harmonic analysis

- Statistical energy analysis

- Transfer path analysis

Electromagnetic Analysis

- Magnetostatic analysis

- Electrodynamic analysis

- Electromagnetic compatibility analysis

Fatigue Analysis

- Damage accumulation analysis

- Rainflow counting analysis

- Crack growth analysis

- Life prediction analysis

- Failure Analysis

Fracture Mechanics Analysis

- Linear elastic fracture mechanics analysis

- Elastic-plastic fracture mechanics analysis

- Cohesive zone analysis

- Crack tip element analysis

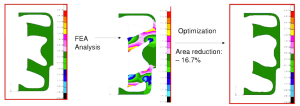

Optimization Analysis

- Design optimization

- Shape optimization

- Topology optimization

- Parameter optimization

Nonlinear Analysis

- Geometric nonlinear analysis

- Material nonlinear analysis

- Contact nonlinear analysis

- Large deformation analysis

At AEG, we pride ourselves on delivering top-notch services that drive product success. Let us help you improve your results with our company’s specialized FEA and consulting services.

Frequently asked questions

What is FEA and why use it?

Finite Element Analysis (FEA) is a simulation method used to design products. It helps find the best material combination and predicts how the product will perform under different loads. FEA helps improve product quality, efficiency, and uptime, leading to increased profitability.

What does the FEA process entail?

The FEA process involves creating a 3D model and dividing it into smaller parts called nodes. Next, allocate materials and structure properties to each node. Then, examine stress, load, and vibration levels thoroughly. The complexity of the project determines the type of FEA analysis used (structural, vibration, fatigue, etc.).

What industries can benefit from FEA services?

Moreover, FEA (Finite Element Analysis) plays a crucial role in assisting various industries such as manufacturing, automotive, aerospace, and construction by:

- Evaluate corrosion

- Predict future corrosion growth

- Detect machine faults and frequency

- Calculate the impact of increased nip loads

How does FEA enhance product quality?

FEA modeling with homogeneous materials in optimal conditions leads to high-quality results. FEA can highlight defects in product design, allowing for necessary improvements to be made.

Can FEA guarantee better quality?

The FEA results are reliable as they take into account the ideal manufacturing conditions and uniform materials, ensuring high-quality outcomes. By using FEA, you can guarantee better quality, efficiency, and uptime for your products.

Can FEA guarantee better quality?

The FEA results are reliable as they take into account the ideal manufacturing conditions and uniform materials, ensuring high-quality outcomes. By using FEA, you can guarantee better quality, efficiency, and uptime for your products.

What services does AEG offer for heat transfer and boundary conditions analysis?

AEG offers heat transfer and boundary conditions analysis using advanced simulation techniques. Our team incorporates all relevant boundary conditions for accurate results. Contact us for more information.