lntroduction

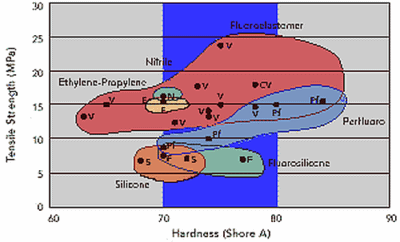

Rubber gasket seals are essential components for preventing leaks and maintaining pressure in various industrial applications. Advances in rubber technology have led to the development of specialized rubber gasket seals that can withstand extreme conditions and offer superior performance.

Rubber is one of the most extensively used gasket and seal materials due to its superior sealing properties. Rubber gasket seals store the force applied during clamp-up and exert back pressure against the flanges to maintain a tight seal. However, it’s important to note that stress relaxation, temperature variations, and rubber swelling or shrinking in the fluid being sealed can decrease this sealing force over time.

Evaluating a given rubber material’s suitability for sealing applications is a crucial step, and the most convenient method for this purpose is stress relaxation. However, the conventional short-term test can be misleading since rubber will function over a wide temperature range between metal flanges in actual applications. Therefore, the current continuous compression stress relaxation (CCSR) test aims to offer an improved method of evaluating rubber compounds.

ARDL Continuous Compression Stress Relaxation Test

The ARDL CCSR apparatus is shown in Figure 1a and Figure 1b. It consists of 5 fixtures placed inside a temperature chamber. In each fixture, the specimen is placed between the base plate and compression plate, and the compression is set by a high-resolution screw adjuster with a lock nut. A load cell is installed in series between the screw adjuster and the plunger and connected to a multi-functional measuring instrument. This instrument is interfaced with a microcomputer through a data acquisition card, and experimental data (force, displacement, temperature, time, etc.) are recorded continuously during a test.

To examine the effect of thermal cycling on the retention of the sealing force of rubber components, an accurate cycling heating and cooling system is required. The temperature chamber built inside the current CCSR apparatus has a thermo-electric plate, and a power supply and a thermo-electric cooling system are used to control the temperature, ranging from -40 °C to +150 °C with a tolerance of ±0.5 °C.

Prior to any test, the surfaces of the base plate and compression plate are carefully cleaned and inspected to ensure they are smooth and free of corrosion. This reduces the friction between the stainless steel plates and ensures the accuracy of the measurements. Two types of specimens are used for the experiments: a cylindrical disc with 13mm in diameter and 4mm in thickness (Type A) and a flat washer with a 5.8 mm I.D., 13 mm O.D., and 4 mm in thickness (Type B). All specimens are die-cut using ASTM slabs.

The specimens are initially compressed by 25% of their thickness unless otherwise noted, and the sealing forces are measured. In the thermal cycling test, the temperature varies from -40 °C to 150 °C. A typical temperature profile is seen in Figure 3, as recorded in an experiment. The calculated increase in strain due to thermal expansion between room temperature (20 °C) and 150 °C was approximately 1.9%.

Experimental Results

Rubber materials are widely used for gaskets and seals, and their sealing properties can be affected by various factors such as stress relaxation and temperature changes. In order to evaluate the suitability of a given rubber material for sealing applications, a continuous compression stress relaxation (CCSR) test has been developed by ARDL.

The CCSR apparatus consists of five fixtures placed inside a temperature chamber, where specimens are compressed between a base plate and compression plate. A high-resolution screw adjuster with a lock nut maintains the compression at the desired constant value. A load cell is installed in series between the screw adjuster and the plunger, and connected to a multi-functional measuring instrument for recording experimental data such as force, displacement, temperature, and time.

In the experimental procedure, two types of specimens were used: a cylindrical disc and a flat washer. The specimens were initially compressed by 25% of their thickness, and the sealing forces were measured. In the thermal cycling test, the temperature varied from -40°C to 150°C. The surfaces of the base plate and compression plate were cleaned and inspected prior to any test to reduce friction and ensure measurement accuracy.

The stress relaxation results for both button and washer specimens tested at 20°C for a period of 24 hours were shown in Figures 4 and 5. The tests were performed at different strain levels of 10%, 25%, and 30%. By normalizing the sealing force with the initial force applied, it was observed that the force retention at different strains followed the same magnitude (Figure 6).

The stress relaxation results at cycling heating and cooling conditions were shown in Figure 7. The sealing forces increased as the temperature increased and decreased as the temperature decreased due to the thermal expansion of rubber materials. Rubber has a higher coefficient of expansion than the metal flanges, which accounts for an increase in sealing force at high temperature and a decrease in sealing force at low temperatures.

The sealing force measured at cycling heating and cooling conditions provides information on the compound’s ability to maintain a seal at conditions to which an actual part may be exposed. The material tested displayed good force retention at high temperature (above 120%). The overall force retention after heating and cooling cycles was above 60%.

Finite element analysis of stress relaxation

Rubber materials are known for their viscoelastic nature, which is characterized by a stress relaxation phenomenon. To understand this behavior, researchers have employed Finite Element Analysis (FEA) to model the stress relaxation of rubber materials. In this article, we will discuss the results of a study that uses FEA to model stress relaxation in rubber materials.

The FEA model consisted of a rubber specimen that was compressed between a metal plate and a rigid surface. A reference node was used to control the movement of the rigid surface and monitor the load. The friction between the rubber block and plates was assumed to be 0.01.

The viscoelasticity of rubber material in the time domain is modeled using Prony method. The dimensionless relaxation modulus (gR), which is independent of the magnitude and direction of straining, is incorporated into the elastic constitutive material models in ABAQUS. The instantaneous elasticity is defined by the uniaxial compression data, while the viscoelastic property is defined by the normalized stress relaxation data.

The proper choice of the elastic constitutive models is critical in modeling rubber’s viscoelastic behavior. The study used Ogden and Arruda-Boyce models, which gave accurate fits to the experimental data. The calculated stress relaxation curves for both button and washer specimens at 20°C showed good agreement with the experimental results.

As cycling temperatures are involved, the effect of temperature on material behavior is introduced through the Williams-Landel-Ferry (WLF) shift function log(A). The calculated stress relaxation curves for both button and washer specimens at cycling temperatures showed good agreement with the experimental data for the first two cycles (room temperature and high temperature), but a discrepancy for the low temperature cycle was observed.

Overall, the FEA model proved to be an effective tool in understanding stress relaxation in rubber materials. The study demonstrated that the proper choice of elastic constitutive models and the incorporation of viscoelastic properties are critical in accurately modeling rubber’s behavior. As rubber materials are widely used in various applications, understanding their viscoelastic behavior is essential in predicting their performance and ensuring their longevity.

Conclusions

In conclusion, the continuous compression stress relaxation tester provides a valuable tool for measuring the sealing force of rubber materials under cycling thermal conditions. By subjecting rubber compounds to continuous compression stress relaxation tests, it is possible to evaluate the suitability of these materials for sealing applications. The Prony series has been used in finite element modeling to successfully simulate the stress relaxation of rubber materials. It was found that the choice of constitutive material models has a significant impact on rubber viscoelasticity.

The force retention at cycling temperatures was also modeled using the WLF shift function, and the results were in good agreement with the experimental data for the first two cycles. However, some discrepancy was found for the low temperature cycle, indicating that further research is needed to better understand the behavior of rubber materials under these conditions.

In summary, the continuous compression stress relaxation tester and finite element modeling provide a more comprehensive understanding of the viscoelastic behavior of rubber materials, which is crucial for designing and selecting appropriate sealing materials. By using these methods, it is possible to develop rubber compounds with improved sealing performance and reliability in a variety of applications.

Research paper

Continuous Compression Stre… by on Scribd