Introduction

Engineered rubber components play a vital role in various industries, from the automotive component market to the aerospace industry. These components are designed to perform specific functions, such as motion accommodation, fluid transfer, and vibration isolation, among others. Surface Science plays an essential role in the development of engineered rubber components, including the use of adhesives, surface preparation, and coatings. The importance of engineered rubber components lies in their ability to provide a solution to various engineering problems, making them indispensable in many applications. In this blog post, we will delve into the latest trends and developments in engineered rubber components, focusing on materials, design technology, surface science, and process technology. Furthermore, advancements in advanced materials technology are being made, which have expanded the possibilities in the development of engineered rubber components. We will also discuss the different product platforms for engineered rubber components, highlighting their significance in various industries. Moreover, we will explore examples of damping rubber components and aircraft elastomer components, emphasizing their importance and the services provided by American Engineering Group. Overall, this blog post aims to provide insights into the advancements and innovations in engineered rubber components, highlighting their critical role in the engineering world.

Product Platforms for Engineered Rubber Components

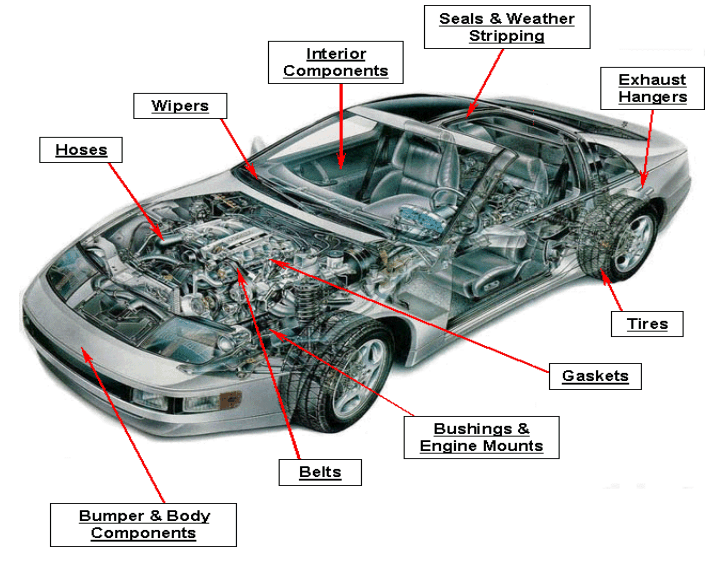

There are several product platforms for engineered rubber components, each with its unique significance and application. First, motion accommodation components are essential in automotive component market and industrial applications, where they allow for flexibility and movement of different parts. Second, fluid transfer components are critical in the transportation of fluids and gases in various industries, such as oil and gas, chemical, and pharmaceuticals. Third, vibration isolation components help reduce the impact of vibrations on different equipment, enhancing their durability and performance. Fourth, power transfer components are used to transmit power from one point to another, such as in conveyor belts or power generators. Fifth, damping components are crucial in reducing the impact of shocks and vibrations on different structures, such as buildings and bridges. Sixth, energy absorption components are used to store and release energy, making them ideal for impact and shock-resistant applications. Lastly, sealing components are used to prevent fluid leakage in different applications. Each product platform plays a significant role in various industries and applications, highlighting the critical importance of engineered rubber components in the engineering world.

Damping Rubber Components Examples

Damping rubber components are critical in various industries, especially in applications that require the reduction of vibrations and shocks. These components are designed to absorb and dissipate energy, preventing it from transferring to other parts of the system. One example of damping rubber components is foundation blocks, which are used to reduce the impact of vibrations on building foundations, machinery, and equipment. The development of damping rubber components involves several aspects, including advanced materials technology, design technology, surface science, and process technology. The choice of materials is crucial in ensuring the performance and durability of the components. Meanwhile, design technology, such as FEA and dynamic analysis, enables the simulation and prediction of the behavior of the components under different conditions. Surface science, on the other hand, plays a vital role in improving the adhesion and durability of the components. Finally, process technology is essential in ensuring the precision and consistency of the components, especially in high-volume manufacturing. Overall, the development of damping rubber components requires a multidisciplinary approach, highlighting the importance of different aspects of engineering in creating effective and reliable solutions.

Advanced Materials Technology

The choice of materials is a critical aspect in the development of engineered rubber components. There are different types of materials used, including natural rubber, synthetic elastomers, and reinforcing fillers. Natural rubber or natural rubber blends are still a popular choice due to their high resistance to cyclical deformation. However, there is a need to ensure the economic value of producers. Meanwhile, synthetic elastomers, mostly driven by the automotive component market, have overcome the limitations of natural rubber in terms of fluid and temperature resistance through the use of hydrogenation and metallocene chemistries. Silicones are also used for high damping and broad temperature range capability. Finally, reinforcing fillers, such as carbon black and silica, are used to improve the mechanical and physical properties of the components. Advanced materials technology continues to drive innovation in the development of engineered rubber components, enabling the creation of high-performance and cost-effective solutions for various industries and applications.

Design Technology

Computational tools have played a significant role in the design of engineered rubber components. Advanced use of tools such as Finite Element Analysis (FEA) and dynamic analysis enable sophisticated nonlinear analysis that was previously impossible. Fatigue prediction, energetic analysis, flow simulations, and full systems integrated analysis are also essential in the design process, enabling engineers to account for time and temperature dependence and fully understand the behavior of the elastomer in the entire system. These advancements have allowed for the creation of highly-engineered products with improved performance and durability. Additionally, the integration of real-time modeling of elastomer behavior has enabled engineers to understand the effects of the elastomer on the full system. Advancements in design technology continue to enable the development of new and innovative engineered rubber components, making them suitable for a wide range of industries and applications.

Surface Science

Surface science plays an important role in the development of engineered rubber components. Adhesives, surface preparation, and coatings are all critical components of surface science that help improve the functionality and durability of engineered rubber components. Adhesives, in particular, have improved in environmental friendliness, flexibility, and fluid and heat resistance. Surface preparation, including improved corrosion control at lower total cost, has also been enhanced through the development of autodeposited aqueous metal treatment/coating systems. Coatings have enabled natural rubber substrates to function in hostile environments. Advancements in surface science have led to improved functionality and durability of engineered rubber components, making them suitable for use in a wider range of industries and applications. As technology continues to evolve, the possibilities for surface science advancements in engineered rubber components are endless.

Process Technology

Process technology plays a crucial role in the development of engineered rubber components. The manufacturing process must ensure complexity reduction, real-time control, and precision control to produce highly-engineered products. The use of computer-controlled mixing technology with closed-loop feedback and real-time control with “corrective” feedback is critical to achieve precision in the manufacturing process. Advancements in injection molding technology have allowed for in-situ adjustments for cure cycles, making it the preferred choice for high-volume automotive and industrial applications. The ability to control transfer rates for multi-layer components is another benefit of injection molding. Overall, advancements in process technology have allowed for the production of highly-engineered rubber components that meet the exacting requirements of modern industries. The continuous improvement of process technology is critical to meet the evolving demands of different industries and applications.

Aircraft Elastomer Components Examples

Aircraft elastomer components play a critical role in ensuring the safety and efficiency of aircraft operations. This section will explain the importance of these components in the aviation industry and provide examples of some of the most common aircraft elastomer components. Additionally, the discussion will delve into the importance of product development, manufacturing, FEA, product design analysis, and project partnership in the development of aircraft elastomer components. Examples of aircraft elastomer components include seals, gaskets, vibration dampers, and shock mounts, all of which are critical in ensuring the safety and comfort of passengers and crew members. The development of aircraft elastomer components requires a high level of expertise, including advanced product design analysis, manufacturing techniques, and FEA. Additionally, project partnership and confidentiality are crucial in ensuring the success of these projects.

American Engineering Group Services

American Engineering Group (AEG) is a company that provides a range of services in the development of engineered rubber components. AEG’s services include product development, manufacturing, FEA, product design analysis, project partnership, confidentiality, and ISO 9001. Each service plays a crucial role in the development of high-quality and innovative engineered rubber components.

AEG’s commitment to innovation, technology, and customer success is evident in the services they provide. The company utilizes the latest advancements in materials technology, design technology, surface science, and process technology to ensure that their clients receive the best products possible. Additionally, AEG values partnerships with their clients and prioritizes confidentiality to ensure that sensitive information is protected.

ISO 9001 certification is another indication of AEG’s commitment to quality and customer satisfaction. This certification ensures that AEG’s processes and services are consistently of high quality and meet international standards. Overall, AEG is dedicated to providing the best possible services to their clients and advancing the field of engineered rubber components through innovation and technology.

Conclusion

In conclusion, engineered rubber components are crucial to various industries, including aviation, the automotive component market, and construction. The importance of different product platforms such as motion accommodation, fluid transfer, vibration isolation, power transfer, damping, energy absorption, and sealing was discussed. The materials used in the development of engineered rubber components include natural rubber, synthetic elastomers, and reinforcing fillers, with each having its benefits and limitations. Advanced materials technology, design technology, surface science, and process technology were also outlined. It was noted that collaboration and partnership are essential in the development of engineered rubber components. Finally, the importance of American Engineering Group’s services in product development, manufacturing, FEA, product design analysis, project partnership, confidentiality, and ISO 9001 was highlighted. Overall, the development of engineered rubber components has seen significant advancements in recent years, making them even more crucial in various industries.