Introduction

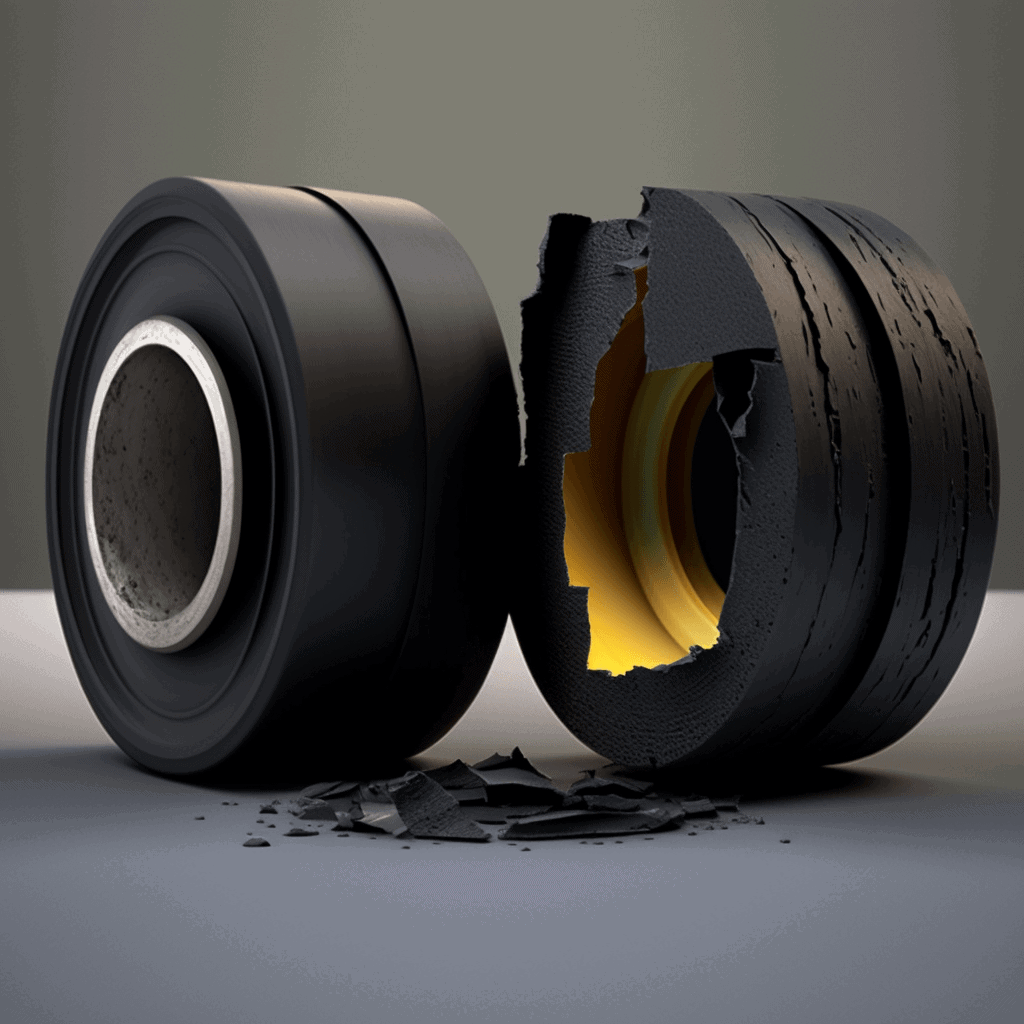

Service life prediction of rubber components involves assessing their durability and lifespan under different service conditions. It is a process of understanding how elastomers behave and change over time. This includes evaluating the effects of temperature, moisture, light, fluids, and mechanical stress on the properties of rubber components. The objective is to predict the service life of elastomers in real-world conditions, without waiting for years of in-service evaluations.

Service life prediction is crucial in engineering design as it sets the limit to the expected lifespan of a product. By predicting the service life of rubber components, engineers can ensure that their products will last for the intended duration without failure. It allows them to select the right materials, optimize the design, and identify potential risks that could lead to product failure. By taking these factors into account, service life prediction helps to reduce costs of maintenance and repair, increase product reliability, and enhance customer satisfaction. Ultimately, service life prediction is a key component of effective product development and engineering design.

The Need for Service Life Prediction

The need for service life prediction is evident in the complex properties and sensitivity of elastomers. Elastomers are materials that can deform under stress and return to their original shape once the stress is removed. However, they are also sensitive to external factors, such as heat, moisture, light, fluids, and mechanical stress, which can cause changes in their properties over time.

Elastomer properties, such as hardness, strength, and elasticity, are essential to understanding their behavior and predicting their service life. These properties can be affected by environmental factors, including temperature and humidity.

Heat can accelerate the aging process of elastomers, leading to stiffness, cracking, and loss of elasticity. Moisture can also affect the properties of elastomers, causing swelling, softening, and reduced strength. Light can cause discoloration and degradation, while fluids can cause chemical reactions that alter the properties of elastomers.

Changes in properties can lead to product failure, which can have serious consequences in engineering applications. Predicting service life helps to identify potential risks, prevent product failure, and ensure the safety and reliability of products in the field.

In engineering applications, predicting service life is crucial for optimizing product design, reducing costs, and improving product performance. By evaluating the service life of elastomers, engineers can determine the best materials and designs for specific applications, and ensure that products will perform as intended throughout their expected lifespan. Ultimately, predicting service life is an essential tool for ensuring product quality, safety, and reliability in engineering design.

Factors Affecting Service Life

Temperature plays a critical role in the service life prediction of elastomers. Elevated temperatures can accelerate the aging process and lead to changes in properties such as hardness, modulus, and elongation. Understanding the effects of temperature is crucial to predicting the service life of rubber components in different applications.

Moisture can significantly affect the service life of elastomers, as it can cause swelling, softening, and reduced strength. Moisture can also facilitate the degradation of elastomers through hydrolysis, oxidation, or other chemical reactions. Understanding the effects of moisture is crucial to predicting the service life of rubber components in humid or wet environments.

Stress is another important factor that affects the service life of elastomers. Mechanical stress can cause changes in properties such as hardness, modulus, and fatigue resistance. Understanding the effects of stress is crucial to predicting the service life of rubber components in dynamic applications, such as in tires or seals.

Fluids can cause chemical reactions that alter the properties of elastomers, leading to degradation and failure. Different fluids can have different effects on elastomers, depending on their chemical composition and physical properties. Understanding the effects of fluids is crucial to predicting the service life of rubber components in applications where exposure to chemicals or oils is common.

Challenges in Service Life Prediction

Service life prediction of elastomers presents challenges due to the difficulties in evaluating the aging process in actual service conditions. Factors such as temperature, humidity, and mechanical stress can interact in complex ways, making it challenging to predict the effects of different environmental conditions on elastomer properties.

It is difficult to evaluate the aging process of elastomers in actual service conditions, as it may take several years to observe the changes in properties. Accelerated testing can provide some insight into the behavior of elastomers over time, but it may not always reflect the actual service conditions.

Elastomers are complex materials with behavior that is affected by a wide range of factors. Their behavior can be influenced by the rate of deformation, temperature, and frequency of loading, among other factors. Understanding and modeling the behavior of elastomers can be challenging, and it requires accurate data and sophisticated models.

Accurate modeling and testing are critical for predicting the service life of elastomers. Different modeling techniques, such as finite element analysis and multi-scale modeling, can be used to simulate the behavior of elastomers under different conditions. Testing methods, such as dynamic mechanical analysis and tensile testing, can provide data to validate the models and improve their accuracy.

Advantages of Service Life Prediction in Engineering Design

Service life prediction provides several advantages in engineering design, such as improved product reliability, reduced costs of maintenance and repair, increased safety and productivity, and enhanced customer satisfaction.

Improved product reliability is a key benefit of service life prediction, as it allows engineers to design products with longer lifetimes and better performance. By predicting the service life of elastomers, engineers can identify potential failure modes and develop strategies to mitigate them.

Service life prediction can also help to reduce the costs of maintenance and repair, as it allows engineers to optimize maintenance schedules and reduce the need for unscheduled downtime. This can result in significant cost savings for industries such as transportation, where downtime can have a major impact on productivity.

Predicting the service life of elastomers can also increase safety and productivity in engineering applications. By designing products with longer lifetimes and better performance, engineers can reduce the risk of failure and improve the overall safety of the product. This can also lead to increased productivity, as there is less downtime due to repairs and maintenance.

Finally, service life prediction can enhance customer satisfaction by providing products that meet or exceed customer expectations. Customers value products that are reliable and have long service lives, and service life prediction allows engineers to design products that meet these expectations.

Conclusion

In conclusion, service life prediction is a critical aspect of engineering design, as it allows engineers to design products that meet performance expectations and have longer lifetimes.

The importance of service life prediction in engineering design cannot be overstated. By understanding the factors that affect the behavior of elastomers and predicting their service life, engineers can design products that are reliable, safe, and cost-effective.

In the rapidly evolving field of engineering, service life prediction will continue to play a crucial role in product development. Advances in modeling and testing techniques, as well as the development of new elastomer materials, will further improve our ability to predict the service life of rubber components and design products that meet the needs of customers and industries.